Why proper disinfection with drain cleaning is important.

Drain cleaning with brushes or high-pressure spray is a thing of the past. Puremed Canada is always looking for new ways to improve pathogen control through research & development. One of the main areas of concern in food processing plants is the maintenance of drain systems, using older methods can cause pathogens to aeronize. While numerous food-processors work tirelessly to maintain and control the growth of harmful organisms, particularly Listeria, in RTE-area drains, many drains have tested positive for these undesirable pathogens.

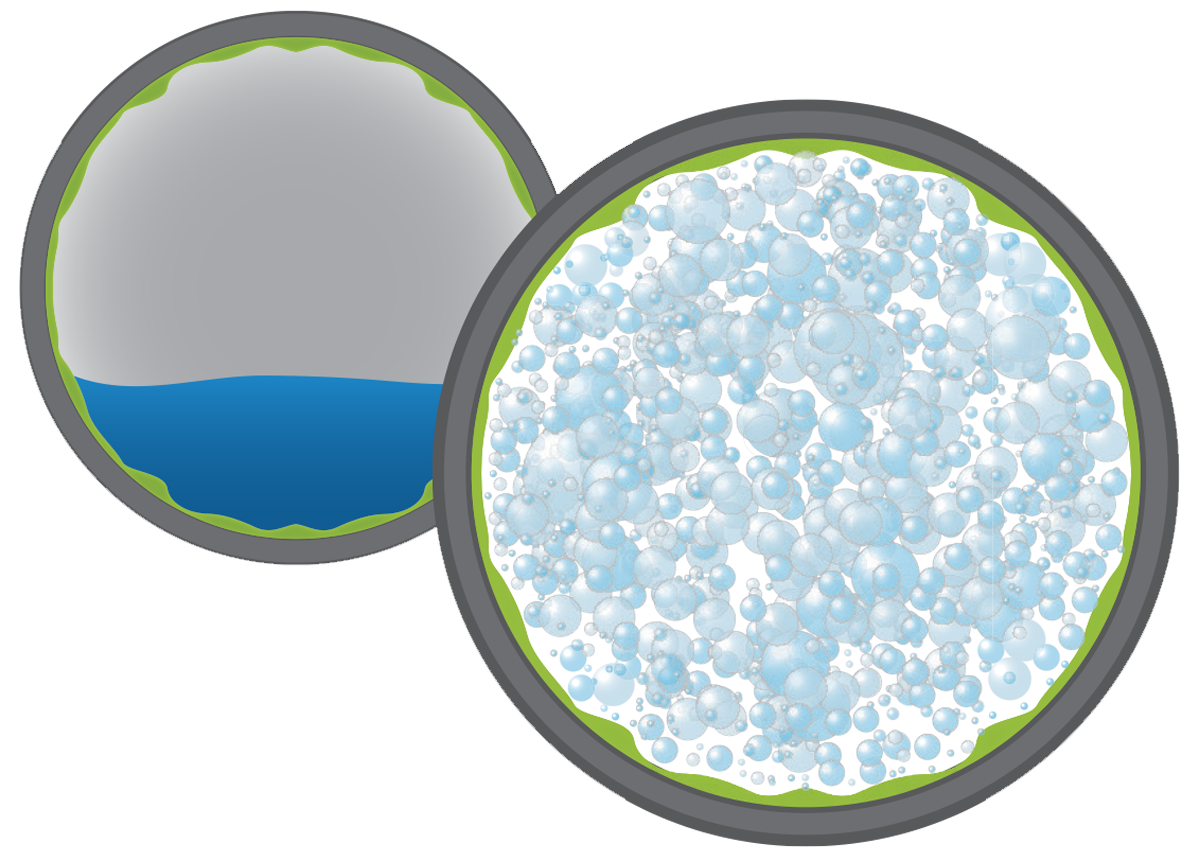

Due to improper drain cleaning services, microorganisms, food residues and different types of bacteria can multiply in drains. Food processors spend extensive amounts of time and money to keep drains sanitized, with little success, especially when biofilm is present.

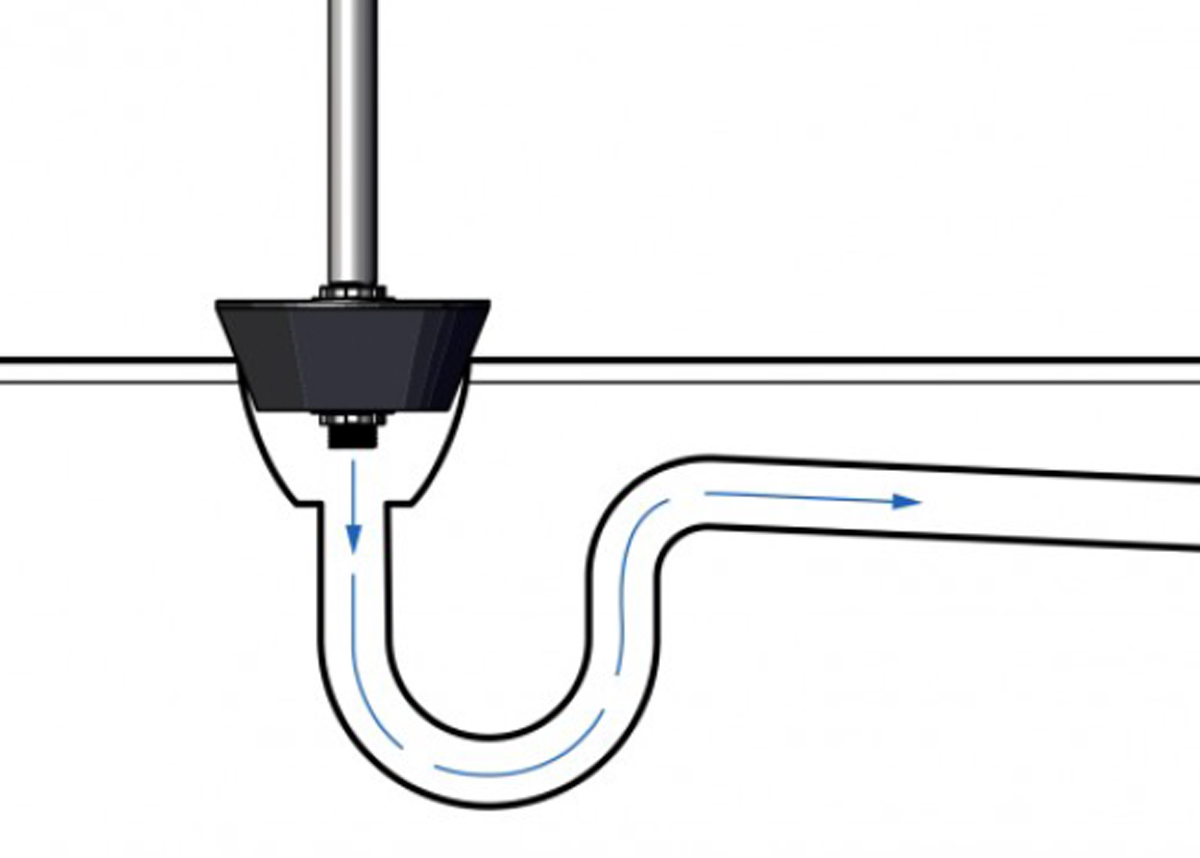

Pathogens in a biofilm are resistant to traditional chemicals. This can occur by clogged drains that will cause contamination and water backups into production areas. Blockages in drains can also create a positive air pressure, which in exchange forces air to flow back from the drains into the production areas, thus spreading pathogens through microbial aeronization.

Microorganisms and bacteria can clog in drains, particularly on drain walls, higher than the normal water levels. As pathogens multiply and grow, they produce a chemical-resistant polysaccharide matrix, which they use to attach themselves to drain surfaces and systems. Drain Cleaning with Foam provides 360° contact within the pipe walls for maximum disinfection and sterilization. Industrial and commercial drain cleaning with foam enables the coating of the entire wall of the pipe while traveling at a longer extension, thus yielding longer contact times while the foam disintegrates slowly.

Restaurants, Healthcare, Manufacturing and Processing facilities are all at risk of contamination through microbial aeronization. Our equipment and expertise is suitable for any drain system and channel.

EXPERTS